The superior way of greenhouse covering

NOWOGREEN®

Powered by Hueck Folien

Perfect conditions for enhanced

greenhouse yields

Your benefits at a glance

- decade-long durability

- enabling perfect conditions for improved plant growth thanks to enhanced light transmission

- highest weather resistance - even against hail (class 3) and strong UV radiation

- self-cleaning properties

- anti-drop coating for unrestricted light transmission

Anti-drop coating

Anti-drop coating for unrestricted light transmission

Hueck Folien has further improved the ETFE film for use in greenhouses with an innovative hydrophilic coating on the inner surface. The coating prevents drops from forming on the film surface due to high humidity in the greenhouse. The rising condensation forms a film of water over the entire surface of the highly transparent, hard-wearing coating, which can flow off the sides in a controlled manner thanks to the design. This also prevents the film from fogging up.

The result: The unrestricted light transmission accelerates plant growth and the prevention of water droplets ensures immaculate plants and crop products without burn marks.

The coating offers high chemical resistance. Any residues of fertilisers or pesticides in the air have no impact on the coating.

Comparison

ETFE vs. Glass

NOWOGREEN® films impress with a long durability of over 30 years and maximum weather resistance. They can withstand extreme weather conditions such as high UV radiation, long periods of heat or cold and hail.

Perfect light conditions are essential for optimum plant growth. Droplets of condensation on the greenhouse covering hinder the light inlet. Recent studies reveal that condensate on the glass can lead to 7 % light loss. When light levels are low, up to 20 % light loss must even be expected.* As a result, the plants are supplied with less light, which inhibits plant growth.

NOWOGREEN® films feature properties that prevent condensation. Our hydrophilic coating on the inside of the film ensures that the rising condensate forms a laminary film of water, which drains off at the sides in a controlled manner. This prevents the film from steaming up and guarantees excellent light and UV transmission. The plants grow faster, remain flawless and provide crops without burn marks. No additional anti-condensation treatment is required.

* Source: Study GTB -1025 by Wageningen University UR

NOWOGREEN® features class 3 hail resistance (according to VKF test specifications no. 22). With an elongation at break of 450 %, the film provides protection against hail damage. Should the film nevertheless break under excessive load, it will only break at one point without shattering. This prevents contamination caused by shards and avoids harvest losses and therefore high costs.

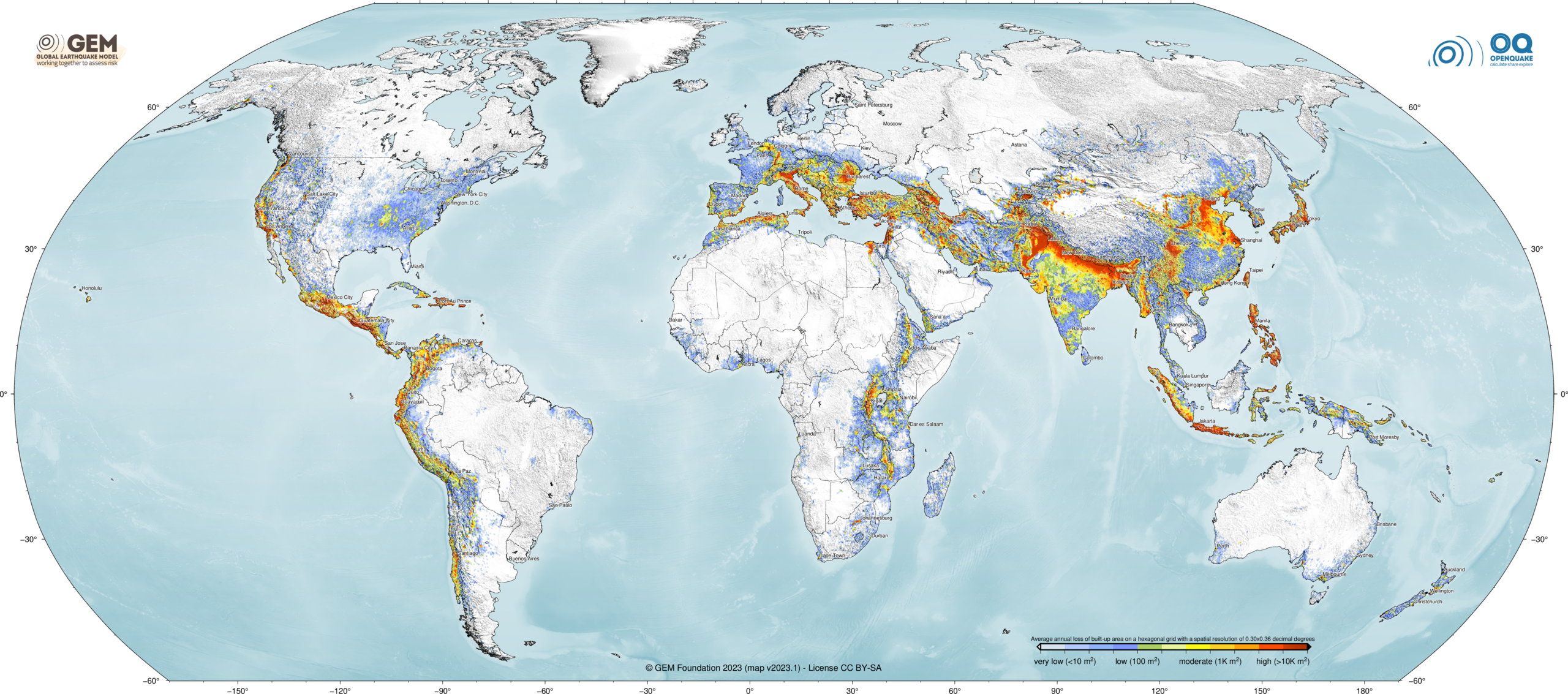

Thanks to its high elongation at break, NOWOGREEN® is also suitable for installation in regions with an increased risk of earthquakes.

Source: V. Silva, A. Calderon, M. Caruso, C. Costa, J. Dabbeek, M.C. Hoyos, Z. Karimzadeh, L. Martins, N. Paul, A. Rao, M. Simionato, C. Yepes-Estrada, H. Crowley, K. Jaiswal (2023). Global Earthquake Model (GEM) Seismic Risk Map (version 2023.1), doi.org/10.5281/zenodo.8409623

In order to store the thermal energy generated by solar radiation during daytime, the films can be installed as two-layer systems. High fluctuations of temperature between day and night are thus minimised, as the EFTE films largely inhibit heat radiation during the night. This allows energy costs for greenhouse operation to be reduced by approximately 30 %.

A NOWOGREEN® greenhouse is approx. 25 % cheaper compared to a traditional glass construction. ETFE films weigh only a fraction of glass. Due to the low weight per unit area of the ETFE film, larger spans are possible compared to glass. Greenhouses with this type of covering therefore have lower static requirements for the construction of the greenhouse, saving costs for support and carrier materials (e.g. steel structures).

Unlike glass, the outer surface of NOWOGREEN® has self-cleaning properties, which enable permanently excellent light and UV transmission. As a result, the film construction can be maintained with minimal effort. Expensive, difficult to obtain maintenance equipment and appropriately trained personnel are no longer necessary to guarantee the best lighting conditions.

Highest resistance against hail

ETFE vs. Float Glass

ETFE vs. Tempered Glass

NOWOGREEN®

Characteristics

- Available options: clear / diffuse

- Film thickness: 100 µm

- Width: 1600 mm

- Elongation at break: 450 %

- Tensile strength: 50 MPa

- Fire protection: B1 (EN 13501-1)

NOWOGREEN® clear

clear

NOWOGREEN® clear offers the highest possible light transmission at all angles of incidence and thus promotes the growth of plants in the greenhouse.

NOWOGREEN® diffuse

diffuse

NOWOGREEN® diffuse scatters the entering light evenly. This completely prevents shadow casting in the greenhouse. The result: flawless crops.

Sustainability

For the environment.

Recycling

ETFE films can be fully recycled back into the primary raw material.

Carbon Footprint

We rely on a 100% European supply chain. This enables short delivery times and prevents long delivery routes.

Our promise

Proven quality

Durability is the result of using the best raw materials, know-how in production processes and reliable quality.

This is why our coatings are regularly subjected to test procedures that guarantee the best possible quality and processability of the films.

FAQs

It is a specially coated film greenhouse with UV-stable film.

- Greater energy utilisation from natural light. ETFE films have an optical transmittance of over 90% and far higher UV light transmittance than glass.

- Utilisation of the entire light spectrum

- Shorter cultivation time due to increased photosynthesis

- Self-cleaning thanks to lotus effect

- Low external energy utilisation

- Even light distribution without casting shadows

- The ETFE film is 100% recyclable and is also UV, acid and temperature resistant.

- The film is flame-retardant and has a self-extinguishing effect (EN 13501-1 / B-s1d0)

- There are no toxic or unknown substances for the UV resistance of the film.

- There is no outgassing (according to AgBB) or leaching of the ETFE film.

- Low thermal transmittance (U-value close to 1W/m²K)

- Due to the low weight per unit area of the ETFE film, larger spans are possible compared to glass.

- CO2 savings possible due to lighter construction compared to glass

Yes, ETFE films offer a high mechanical strength of over 40 N/mm².

The durability of ETFE films is over 30 years. This film has been used in numerous architectural projects since the 1990s. One well-known example is the Allianz Arena in Munich. An ETFE cushion construction was realised here.

- Thanks to the hydrophilic coating, no water droplets form on the inside due to condensation. The condensation runs off along the film. This coating therefore enables greater light transmission.

- By preventing the formation of droplets, there is no lens and burn-in effect on the plants.

No, due to the self-cleaning effect (lotus effect), the optical transparency remains at a high level.

Special aluminium clamping profiles are required. Please contact us for more information.

The raw material ETFE is identical. The difference with NOWOGREEN® is the improved, permanent anti-drop coating. The improved anti-drop effect enables the best light transmission. No subsequent treatment due to degradation is required. The entire NOWOGREEN® supply chain is located within Europe.

Get in touch

*) Mandatory field

Read our privacy policy here.

Tensile Structure

Superior functionality

As a long-standing partner of the best manufacturers of architectural film systems and architects, we guarantee absolute functional reliability.

Our innovative coatings provide the films with special properties: from innovative shading to high UV stability, resistance to hail, wind and weather to hydrophilic properties.