ArctensFascinating designs that satisfy the highest demands

Arctens

Printed ETFE solutions

When durability and maximum design flexibility are required, ETFE is the solution for architectural projects. The transparent films are perfect for covering roofs and facades. The customised printing of the ETFE films enables shading solutions that meet all requirements and provide an ideal indoor environment.

Your Partner: Hueck Folien

20 years of experience in ETFE film coating

As a long-standing partner of the best manufacturers of film architectural systems and architects, we guarantee complete functional reliability.

Being a experienced specialist in film coating, roll-to-roll-processing is our daily business. Our coatings give stadiums, hotels and shopping malls around the world an exceptional look - always combined with outstanding functionality and reliable quality. Enabling extraordinary facade and roof constructions.

Functionality

perfect light conditions

pleasant room ambience

endless design possibilities

Design

diverse colour options

various printing patterns

meeting all architectural requirements

Durability

decades of longevity

withstanding all weather conditions

low maintenance effort

Arctens

Arctens: Features

The light transmission and thus the lighting and temperature in a building can be controlled by the printing on the film. On request, the coating can be customised according to a specific G-value.

Depending on the printing on the surface of the transparent ETFE film, the entering sun rays can be reflected and the light transmission reduced. The higher the optical density of the print (print intensity), the higher the reflection value and the cooler the temperature in the inside. The visual translucency is retained and ensures perfect lighting conditions inside the building.

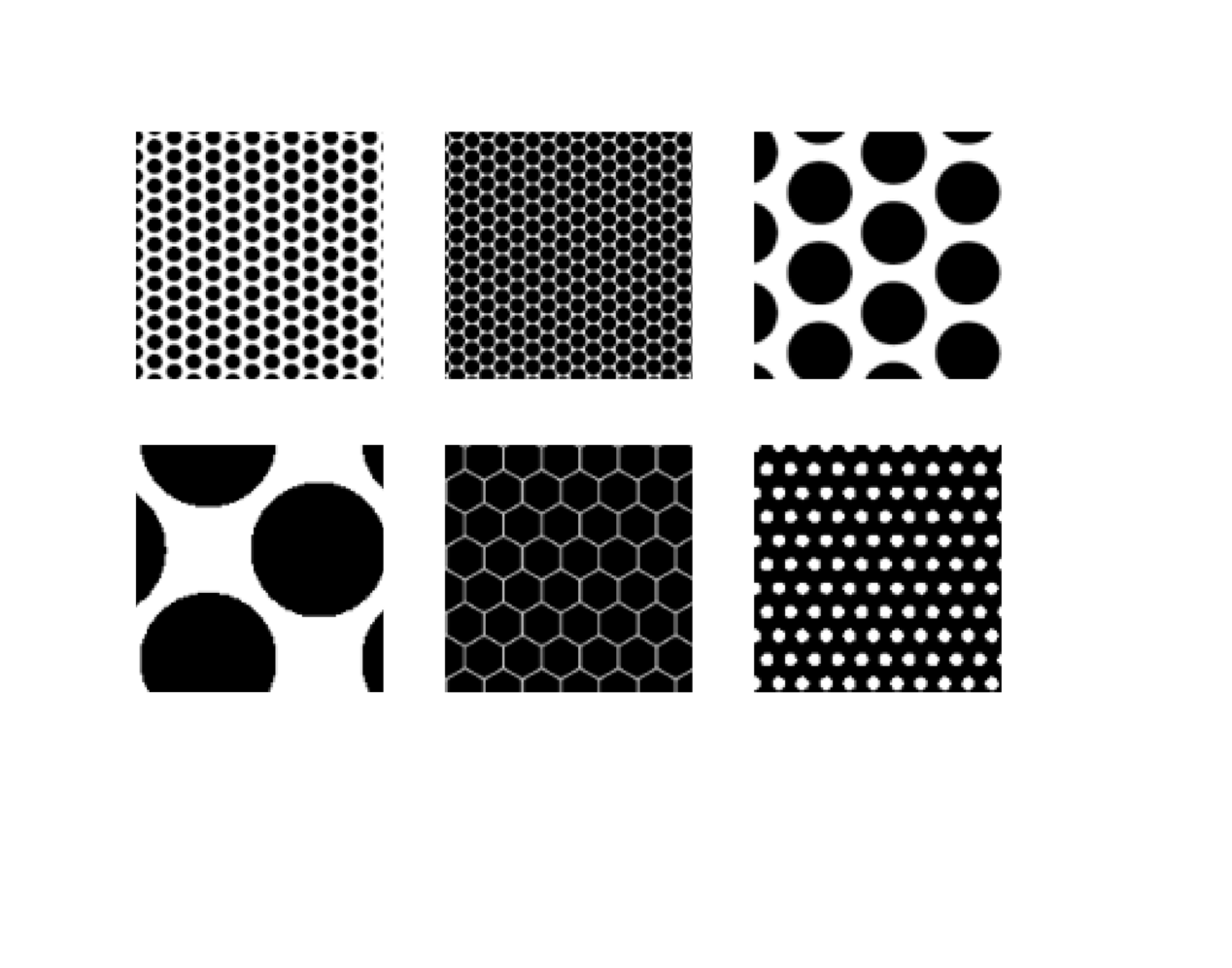

We offer a wide selection of predefined standard patterns for printing.

Our colour range includes silver, gold, copper (each in light, medium and dark shades) and white. The variety of possible combinations of patterns and colours enables customer-specific realisations that meet all requirements in terms of functionality and appearance.

All colours and patterns are suitable for both single-layer and cushion systems.

ETFE films are lightweight, yet extremely stable and durable. This makes the material ideal for architectural applications. Whether roofs or facade coverings: ETFE films enable unique building shapes that would be difficult to realise with glass.

Tensile architectural systems are extremely durable. The membrane constructions can withstand high UV radiation, temperature fluctuations as well as wind and weather for long periods without material fatigue (discolouration, embrittlement, etc.) over time. Thanks to the high elongation at break, ETFE coverings also offer the best protection against hail without shattering. This makes the material suitable for use in all climate zones.

The benefits at a glance

- lightweight

- durable

- lotus effect: self-cleaning surface (low maintenance)

- weather resistant

- construction and design flexibility

Solutions

Single Layer

Single layer systems allow almost unlimited architectural possibilities and more diverse design options compared to glass. An additional coating protects the coloured functional printing and thus enables single-layer installation.

Cushion Systems

For cushion systems, two layers of film are welded at the edges and filled with air. This ultimately creates the cushion-like shape. The inner layer is printed.

Colours

- Silver

- White

Patterns

ETFE Construction

Technical details

- Tensile Strenght: 50 MPa

- Elongation at break: 450 %

- diverse colour options

- G-value: 0.05 - 0.85

- Film thickness: 100 - 500 micron

- Max. printing width: 1510 - 1530 mm

Projects and references

When it comes to designing a building, ETFE films grant the highest freedom in design and shape. This is how unique architecture is created.

Together with our partners we have already realised numerous projects for different applications all over the world.

Quality

Reliable performance.

Ensured in every project.

Longevity stems from the best raw materials, manufacturing expertise and guaranteed quality.

For this reason, our coatings undergo regular internal testing to ensure the best possible film quality and processability.

Before proceeding with any project, we carry out long-term print tests. Upon successful completion of these tests, we issue a certificate of guarantee to assure our customers of the durability of the printing.

FAQs

The dimensions of the raw film are usually 1550 mm. Due to the printing process, the printing width is slightly smaller depending on the print design (1510 mm to 1530 mm).

The minimum order quantity is 500 m2.

No, pre-treatment is not necessarily required. It is carried out inline during the printing process (corona treatment).

Our high-performance printing is covered by a 10-year guarantee.

Double or multi-layer films can be welded to form cushion systems. The welding of pockets or the attachment of piping systems is also possible. We can recommend several partners within our network for this welding process.

Depending on the print design and its optical density, we will provide you with the spectral data required to calculate these values.

We print films from 100 microns to max. 500 microns.

Contact

Felix Ratzenberger

Sales Manager Design

Karim Wieser

Technical Product Management